Automation is changing industries, improving efficiency and safety across the board.

For many industries, automated valves and control systems are essential for streamlining processes, reducing costs, and improving accuracy. By relying on automated systems, companies can enhance performance while minimizing manual effort and error.

In this article, we’ll explore how automated valves and control systems benefit modern industry.

What Are Automated Valves and Control Systems?

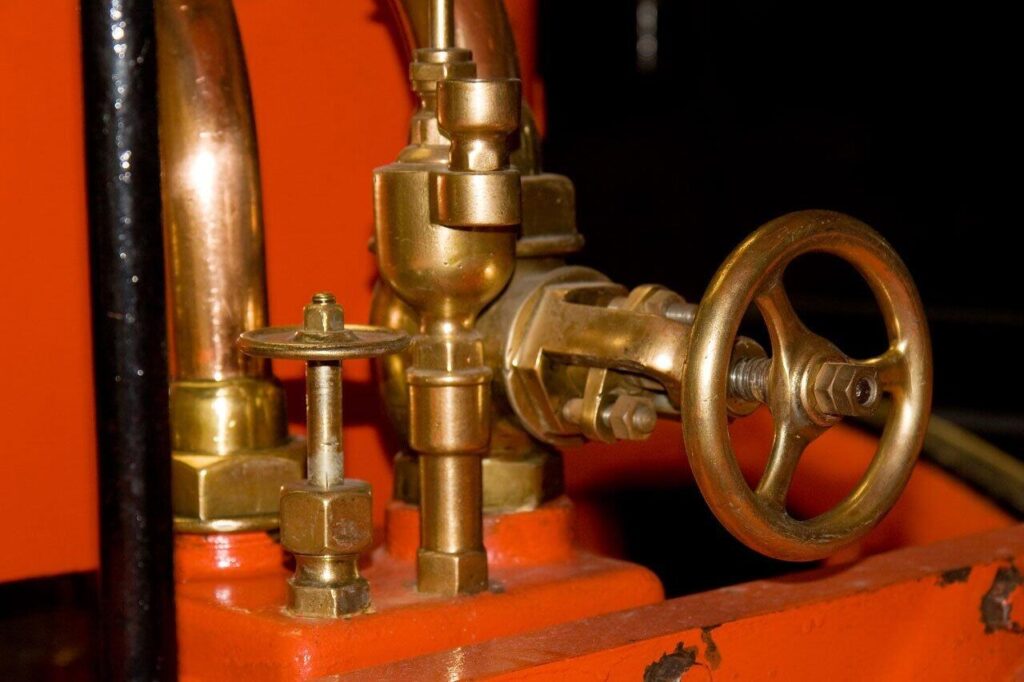

Automated valves and control systems regulate the flow, pressure, and temperature of liquids and gases in various settings, from manufacturing to water treatment plants.

These systems are designed to work automatically, without constant human supervision. Automated valves use sensors, actuators, and software. They can adjust to changing conditions in real-time.

Many industries rely on these systems to manage their processes. This includes oil and gas, chemical processing, and food and beverage. This valve company, for example, helps various industries. It provides solutions to improve their performance and control.

Key Benefits of Automation in Valves and Control Systems

Automating valves and control systems benefits industries. It makes processes faster, safer, and more reliable.

Increased Efficiency and Precision

One of the main advantages of automated valves and control systems is improved efficiency. Automation allows processes to run smoothly, without manual adjustments. This enables continuous production.

Automated systems can respond instantly to changes. They ensure the flow rates and pressures are exactly as required. This level of precision helps reduce waste and ensures consistent quality in the final product.

Enhanced Safety

In industries that handle hazardous materials, safety is a top priority. Automated valves and control systems improve safety. They reduce workers’ direct contact with dangerous substances.

These systems can quickly detect leaks and blockages. They can shut down equipment to prevent accidents. This reduces the risk of injury and ensures a safer working environment for employees.

Lower Operational Costs

While valve automation involves an initial investment, it often pays off by lowering long-term costs. Automated systems reduce manual labor, which can significantly cut down on staffing expenses.

Furthermore, automated valves and control systems often lead to reduced maintenance costs. Real-time monitoring of the system can help companies. They can fix issues early, avoiding costly repairs and downtime.

Real-Time Monitoring and Data Collection

Automated systems track conditions within valves and controls. They provide data on system performance. This data lets companies make informed decisions about:

- maintenance

- production

- quality control

With this data, managers can find inefficiencies. They can then adjust operations to keep peak performance. Also, historical data from automated systems helps forecast and plan production needs.

Applications of Automated Valves and Control Systems

Automated valves and control systems are crucial in a variety of applications, including:

- Oil and Gas

- Water Treatment

- Chemical Processing

- HVAC

Each of these applications benefits from less manual effort and more accuracy. So, valve automation is a valuable addition to any process.

Embracing the Future of Valves and Control

Automated valves and control systems are transforming industries. They improve efficiency, safety, and cost-effectiveness. With real-time monitoring, companies can meet production demands. They can also maintain high standards. Enhanced precision and reduced maintenance help them do this.

As more companies adopt these technologies, the benefits become even clearer. To find reliable valves and control systems, consider this valve company. It offers a range of valve automation solutions for industry needs.

For more cool reads and a ton of knowledge, make sure to visit our blog!