\

Mastering the Allen Wrench: Complete Tips, Techniques, and Pro-Level Uses for DIY Enthusiasts

The Allen wrench, often referred to as a hex key, is one of the most underestimated tools in any toolbox. Despite its small size and simple design, it plays a critical role in countless mechanical, household, and professional applications. From assembling flat-pack furniture to performing precision bicycle adjustments and intricate appliance repairs, the Allen wrench delivers control, accuracy, and efficiency that many tools cannot match.

Understanding how to properly use an Allen wrench goes far beyond simply inserting it into a screw and turning. When used incorrectly, it can strip fasteners, damage materials, and lead to frustration. When used correctly, it becomes a powerful extension of your hand, allowing you to work faster, cleaner, and with greater confidence.

This in-depth guide explores everything you need to know about using an Allen wrench like a professional. Whether you are a beginner or an experienced DIYer, mastering these techniques will significantly improve your results and extend the lifespan of both your tools and fasteners.

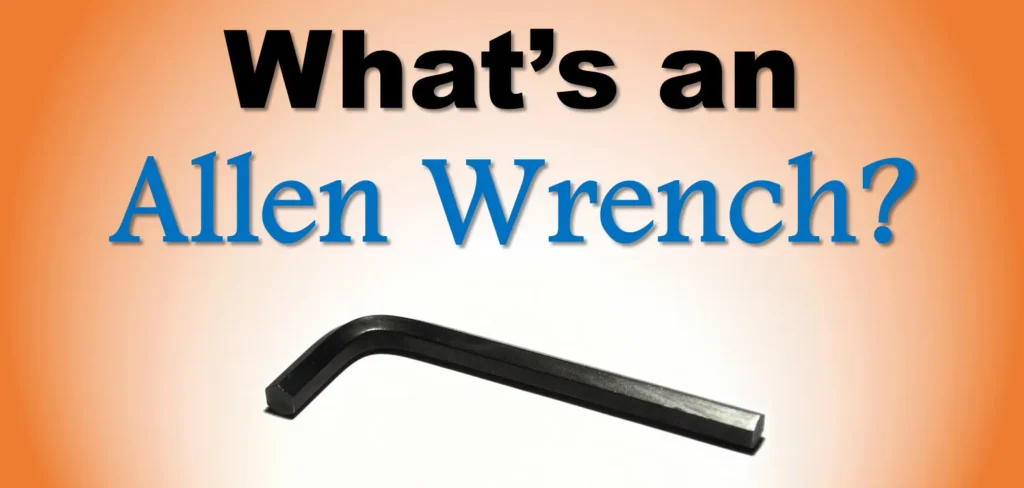

Understanding What an Allen Wrench Is and Why It Matters

An Allen wrench is a hand tool designed to drive fasteners with a hexagonal socket. Unlike traditional screwdrivers that apply force from a single edge, the Allen wrench distributes torque evenly across six contact points inside the fastener. This design reduces slippage and allows for higher torque application in compact spaces.

The tool is typically L-shaped, offering two working ends of different lengths. This simple structure provides versatility, allowing the user to balance torque and control depending on the task. Allen wrenches are available in metric and imperial sizes, and using the correct measurement system is essential to prevent damage.

Their importance lies in precision. Many modern products rely on hex fasteners because they offer strength, clean aesthetics, and compact design. Without proper Allen wrench skills, working with these products becomes difficult and risky.

Choosing the Correct Allen Wrench Size Every Time

Selecting the correct size is the most critical step when using an Allen wrench. A wrench that is even slightly too small or too large can round the edges of the fastener, making removal nearly impossible.

Always ensure the wrench fits snugly into the hex socket with no wobble. If you feel movement inside the screw head, stop immediately and try a different size. Metric and imperial sizes are not interchangeable, even if they appear close.

Investing in a high-quality set with clearly labeled sizes helps eliminate guesswork. Color-coded or ball-end sets can further simplify size selection, especially when working quickly or in low-light conditions.

Proper Grip Techniques for Maximum Control and Torque

How you hold an Allen wrench directly impacts performance and safety. The L-shaped design allows for multiple grip styles, each suited to different situations.

Using the long arm provides increased reach and control, ideal for fasteners located in recessed or awkward spaces. The short arm, when used as the driving end, allows for greater torque, making it ideal for loosening stubborn screws or securing fasteners firmly.

Always apply pressure straight along the axis of the fastener. Angled force increases the risk of stripping the hex socket. Smooth, steady motion is far more effective than quick, forceful jerks.

Understanding Torque and Avoiding Over-Tightening

Torque management is one of the most overlooked aspects of Allen wrench usage. Applying too much force can strip threads, crack materials, or permanently damage fasteners. Applying too little force can cause loosening over time.

Begin tightening slowly until resistance increases. Once the fastener feels secure, stop. If resistance suddenly drops, it may indicate stripping. In professional environments, torque-limiting Allen keys are often used to ensure precise tightening without damage.

Learning to “feel” proper torque takes practice, but it is one of the most valuable skills for any DIY enthusiast.

Using Ball-End Allen Wrenches for Hard-to-Reach Areas

Ball-end Allen wrenches feature a rounded tip that allows the tool to engage fasteners at an angle. This design is especially useful in confined spaces where straight access is impossible.

While ball-end wrenches offer flexibility, they should not be used for high-torque applications. Their angled engagement reduces surface contact, increasing the risk of slipping under heavy force.

Use ball-end tools for fast turning and positioning, then switch to a standard flat-end wrench for final tightening.

Lubricating Stubborn or Corroded Fasteners

When encountering a stuck hex screw, brute force is rarely the solution. Applying penetrating oil allows lubrication to seep into the threads, breaking down rust and debris.

Allow the lubricant to sit for several minutes before attempting removal. Gently tapping the fastener can help the oil penetrate deeper. Always ensure the wrench is fully seated before turning.

This approach significantly reduces tool wear and prevents stripped fasteners.

Maintaining and Storing Allen Wrenches Properly

Tool maintenance directly affects performance. Dirty or damaged Allen wrenches reduce grip quality and increase the likelihood of fastener damage.

Clean wrenches after use, especially when working with grease or metal shavings. Store them in organized holders to prevent bending or loss. Regularly inspect the tips for rounding or wear, replacing any compromised tools immediately.

High-quality hardened steel wrenches last significantly longer and maintain precise edges even under heavy use.

Using Extensions and Handles for Added Leverage

For fasteners located deep inside assemblies, Allen wrench extensions can be extremely useful. These attachments increase reach without sacrificing alignment.

T-handle Allen wrenches provide superior comfort and torque distribution, making them ideal for repetitive tasks or larger fasteners. They reduce hand fatigue and improve accuracy, especially during prolonged projects.

Choosing the right accessory transforms the Allen wrench from a simple tool into a versatile system.

Common Applications Where Allen Wrenches Excel

Allen wrenches are used across countless industries and everyday tasks. Their compact design and precision make them indispensable.

| Application Area | Typical Use |

|---|---|

| Furniture Assembly | Securing frame joints and hardware |

| Bicycle Maintenance | Adjusting seats, handlebars, brakes |

| Automotive Repairs | Working on interior panels and engine components |

| Electronics | Opening cases and mounting components |

| Appliances | Accessing internal fasteners for maintenance |

Understanding these applications helps you anticipate the right tool setup for each task.

Preventing Stripped Screws and Fastener Damage

Stripped screws are often caused by incorrect tool size, poor alignment, or excessive force. Prevention starts with patience and preparation.

Always clean debris from the hex socket before inserting the wrench. Seat the tool fully and apply controlled pressure. If resistance feels unusual, stop and reassess.

When removing stubborn screws, tightening slightly before loosening can help break resistance without damage.

Metric vs Imperial Allen Wrenches Explained

One of the most common mistakes is mixing metric and imperial Allen keys. Even small size differences can cause serious damage.

Metric sizes are measured in millimeters and are commonly used in European and Asian products. Imperial sizes are measured in inches and are common in older or American-made items.

Keeping separate, clearly labeled sets ensures accuracy and prevents accidental misuse.

Why Allen Wrenches Are Essential for DIY Mastery

The Allen wrench embodies efficiency through simplicity. It requires minimal space, offers exceptional control, and adapts to countless tasks. Mastering its use builds confidence and opens the door to more complex projects.

By understanding size selection, torque control, proper grip, and maintenance, you elevate your skill level and reduce costly mistakes. The Allen wrench is not just a tool—it is a gateway to precision craftsmanship.

Conclusion: Unlocking Professional Results with a Simple Tool

Mastering the Allen wrench transforms everyday tasks into smooth, frustration-free experiences. With the right techniques, proper maintenance, and thoughtful application, this small tool becomes one of the most powerful assets in your DIY arsenal.

Whether assembling furniture, maintaining equipment, or tackling detailed repairs, the Allen wrench proves that true effectiveness lies not in complexity, but in understanding. By applying the insights from this guide, you can approach every project with confidence, precision, and professional-level results.