Vise grips, a fundamental tool in any toolbox, are indispensable for both professionals and hobbyists. Known for their versatility and gripping power, vise grips can clamp, hold, and manipulate materials with precision. This comprehensive guide explores the history, types, and myriad uses of vise grips, providing detailed insights into why this tool remains a staple in workshops around the world.

History of Vise Grips

Early Innovations

The story of vise grips begins in the early 20th century. The invention of the vise grip is credited to William Petersen, a Danish blacksmith, who immigrated to the United States. In 1921, Petersen designed a new type of pliers that could lock onto objects with a tight grip. He called his invention “Vise-Grip” and secured a patent for it in 1924.

Development and Popularization

Petersen’s original design featured a mechanism that allowed the tool to lock in place, providing a secure hold without constant pressure from the user. This innovation quickly gained popularity among craftsmen and industrial workers. By the mid-20th century, the Vise-Grip brand became synonymous with locking pliers.

Modern Advancements

Over the years, the design and functionality of vise grips have evolved. Modern versions incorporate ergonomic handles, adjustable pressure settings, and enhanced materials for durability. Today, various manufacturers produce vise grips, but the fundamental principles of Petersen’s original design remain intact.

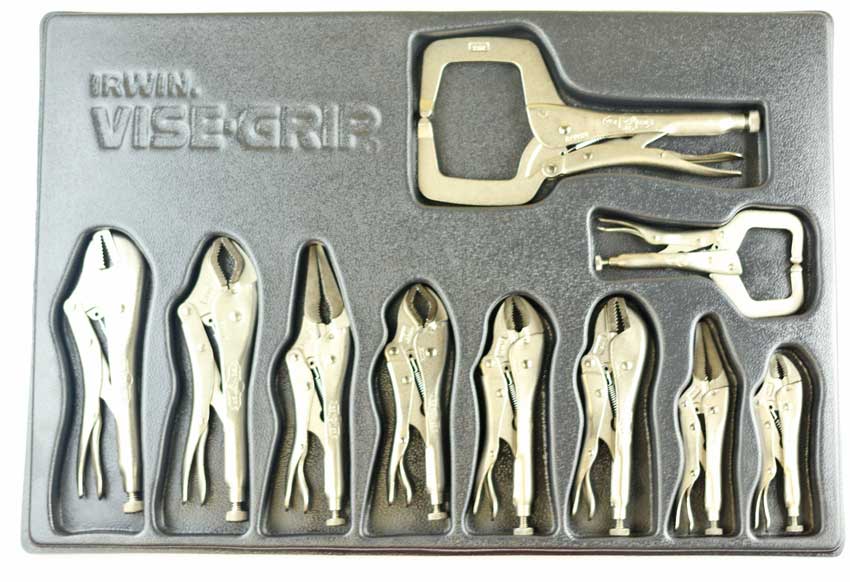

Types of Vise Grips

Vise grips come in various shapes and sizes, each designed for specific applications. Here are the most common types:

Standard Vise Grips

Standard vise grips feature straight jaws and are suitable for general-purpose clamping and holding. These tools are versatile and can be used in numerous applications, from woodworking to automotive repair.

Curved Jaw Vise Grips

Curved jaw vise grips have jaws that curve inward, providing a stronger grip on round objects such as pipes and bolts. This type of vise grip is particularly useful in plumbing and automotive tasks where rounded surfaces are common.

Needle Nose Vise Grips

Needle nose vise grips have long, slender jaws that can reach into tight spaces. They are ideal for precision tasks and delicate work, such as electronics repair and jewelry making.

C-Clamp Vise Grips

C-clamp vise grips feature a C-shaped jaw that can clamp onto larger, flat surfaces. These tools are often used in welding and metalworking, where a wide grip is necessary to hold large pieces securely.

Chain Vise Grips

Chain vise grips use a chain that wraps around irregularly shaped objects, providing a secure hold. This type is particularly useful for clamping pipes and other cylindrical objects.

Sheet Metal Vise Grips

Sheet metal vise grips have wide, flat jaws designed to hold sheet metal firmly. They are commonly used in automotive bodywork and other applications involving thin metal sheets.

Welding Vise Grips

Welding vise grips are specially designed to withstand high temperatures and provide a strong hold on metal pieces during welding. They often feature additional adjustments for precise clamping.

Components of Vise Grips

Understanding the components of vise grips is essential for proper usage and maintenance. Here are the key parts of a typical vise grip:

Jaws

The jaws are the gripping surfaces of the vise grip. They come in various shapes and sizes depending on the tool’s intended use. The material and design of the jaws determine the tool’s gripping strength and durability.

Adjustment Screw

The adjustment screw, located at the end of the handle, allows the user to set the tool’s jaw width and clamping pressure. By turning the screw, the user can adjust the grip to accommodate different sizes of objects.

Locking Mechanism

The locking mechanism is the feature that distinguishes vise grips from regular pliers. It consists of a lever and a spring that allow the jaws to lock in place once the desired pressure is applied. This mechanism provides a secure hold without continuous pressure from the user.

Handles

The handles of vise grips are typically made of metal, coated with a non-slip material for a comfortable grip. Ergonomic designs enhance user comfort and reduce hand fatigue during extended use.

Uses of Vise Grips

Vise grips are incredibly versatile and can be used in a wide range of applications. Here are some of the most common uses:

Gripping and Holding

The primary function of vise grips is to grip and hold objects securely. Whether you’re working with wood, metal, or plastic, vise grips provide a reliable hold, allowing you to work on the object without it moving.

Turning and Twisting

Vise grip’s can be used to turn and twist objects that are difficult to manipulate by hand. For example, they can be used to loosen stubborn bolts or nuts, twist wires, or bend metal.

Clamping for Welding

In welding, vise grip’s are used to clamp metal pieces together, ensuring they stay in place while being welded. This is critical for achieving precise and secure welds.

Removing Stripped Screws and Bolts

One of the most frustrating issues in any workshop is dealing with stripped screws or bolts. Vise grip’s can grip the damaged head firmly, allowing you to twist and remove the screw or bolt with ease.

Holding Objects for Soldering

When soldering electronic components, vise grip’s can hold small parts securely, freeing up your hands to work with the soldering iron and solder.

Bending and Shaping Metal

Vise grip’s can also be used to bend and shape metal. By clamping the metal in the jaws and applying pressure, you can achieve precise bends and shapes.

Emergency Tool

Due to their versatility, vis’e grips are often used as an emergency tool for various tasks. They can act as makeshift wrenches, pliers, or clamps in situations where the appropriate tool is not available.

How to Use Vise Grips

Using vis’e grips effectively requires understanding the proper techniques. Here are the steps to use vis’e grips correctly:

Step 1: Adjust the Jaw Width

Turn the adjustment screw to open the jaws wide enough to fit around the object you want to grip. Ensure that the jaws can close tightly around the object for a secure hold.

Step 2: Position the Jaws

Place the jaws of the vise grips around the object. Ensure that the object is positioned correctly within the jaws for optimal grip.

Step 3: Squeeze the Handles

Squeeze the handles together until the jaws lock in place around the object. You will hear a clicking sound, indicating that the locking mechanism has engaged.

Step 4: Adjust the Grip

If necessary, adjust the grip by turning the adjustment screw. This allows you to increase or decrease the clamping pressure without releasing the jaws.

Step 5: Release the Lock

To release the object, pull the release lever located between the handles. This disengages the locking mechanism, allowing the jaws to open.

Safety Tips for Using Vise Grips

While vise grip’s are generally safe to use, following proper safety guidelines is essential to avoid accidents and injuries. Here are some safety tips:

Wear Protective Gear

Always wear protective gear, such as gloves and safety glasses, when using vis’e grips. This protects your hands and eyes from potential hazards.

Use the Right Tool for the Job

Select the appropriate type of vise grip for the task at hand. Using the wrong tool can result in poor performance and increased risk of injury.

Check for Damage

Before using vis’e grips, inspect them for any signs of damage, such as cracks or worn-out jaws. Damaged tools can fail unexpectedly and cause accidents.

Apply Even Pressure

When using vis’e grips, apply even pressure to avoid slipping or damaging the object. Avoid excessive force, as it can damage both the tool and the object.

Store Properly

Store vis’e grips in a dry, secure location to prevent rust and damage. Keeping them in good condition ensures they are always ready for use.

Maintaining Vise Grips

Proper maintenance of vis’e grips ensures their longevity and performance. Here are some maintenance tips:

Clean Regularly

Clean the vis’e grips after each use to remove dirt, grease, and debris. Wipe them down with a clean cloth and use a brush to remove stubborn residue.

Lubricate Moving Parts

Apply a light coat of oil to the adjustment screw and other moving parts to keep them functioning smoothly. This prevents rust and ensures easy adjustments.

Sharpen the Jaws

If the jaws become dull, use a file to sharpen them. Sharp jaws provide a better grip and reduce the risk of slipping.

Store in a Dry Place

Store vis’e grips in a dry place to prevent rust and corrosion. Using a toolbox or tool chest with a dehumidifier can help maintain optimal conditions.

Inspect Regularly

Regularly inspect vis’e grips for signs of wear and damage. Replace any worn-out parts or tools that show significant signs of damage to maintain safety and performance.

Advanced Techniques and Tips

For those looking to get the most out of their vis’e grips, here are some advanced techniques and tips:

Using Vise Grips as a Clamp

Vis’e grips can serve as a makeshift clamp in various situations. To use them as a clamp, adjust the jaw width to the desired size and lock the jaws in place around the objects you want to hold together.

Creating Custom Jaws

For specialized tasks, you can create custom jaws by attaching materials like rubber or plastic to the existing jaws. This provides a more secure grip on delicate or irregularly shaped objects.

Increasing Leverage

For tasks requiring extra leverage, you can use a pipe or metal rod over the handles of the vis’e grips. This provides additional force, making it easier to manipulate stubborn objects.

Combining with Other Tools

Vis’e grips can be combined with other tools to enhance their functionality. For example, using vis’e grips in conjunction with a wrench can provide a more secure grip on bolts and nuts.

Precision Work

For precision work, use needle nose vise grips. Their slender jaws allow you to reach into tight spaces and hold small objects with precision.

Choosing the Right Vise Grips

Selecting the right vis’e grips depends on the specific needs of your tasks. Here are some factors to consider when choosing vis’e grips:

Task Requirements

Consider the tasks you will be performing with the vis’e grips. Different tasks may require different types of vis’e grips, such as standard, needle nose, or C-clamp.

Jaw Design

Choose a jaw design that matches the objects you will be gripping. Curved jaws are ideal for round objects, while flat jaws are better for flat surfaces.

Size and Capacity

Select a size and capacity that match the objects you will be working with. Larger vis’e grips can handle bigger objects, while smaller ones are suitable for delicate tasks.

Material and Durability

Look for vis’e grips made from high-quality materials, such as chrome-vanadium steel. Durable materials ensure the tool’s longevity and performance.

Brand and Warranty

Choose reputable brands that offer warranties on their tools. A good warranty provides peace of mind and ensures you are getting a quality product.

Conclusion

Vi’se grips are an essential tool in any workshop, offering versatility, strength, and reliability. From their invention in the early 20th century to modern advancements, vis’e grips have remained a staple for professionals and hobbyists alike. Understanding the different types, uses, and maintenance of vis’e grips ensures you can make the most of this invaluable tool.

Whether you’re gripping, twisting, clamping, or holding, vis’e grips provide the power and precision needed to get the job done. By following the guidelines and tips provided in this comprehensive guide, you can enhance your skills and achieve better results in your projects.