The metal fabrication industry is evolving rapidly, driven by advancements in technology, sustainability demands, and the need for more efficient manufacturing processes. As industries seek innovative solutions to improve product performance and operational efficiency, the role of precision metal components has become more critical than ever.

Key Trends in Metal Fabrication

The following trends are shaping the future of metal fabrication and influencing how industries approach their manufacturing needs:

1. Automation and Robotics

Automation is revolutionising metal fabrication, enhancing precision, consistency, and efficiency. Robotic systems and automated machinery are streamlining processes such as:

- Laser cutting and welding

- CNC machining

- Assembly and finishing operations

These technologies not only reduce production times but also improve product quality by minimising human error and ensuring uniformity across batches.

2. Sustainable Manufacturing Practices

Sustainability has become a major focus for manufacturers worldwide. In the metal fabrication industry, efforts to reduce environmental impact include:

- Adoption of energy-efficient machinery

- Recycling of scrap metal to minimise waste

- Implementation of eco-friendly coatings and surface treatments

Sustainable practices not only support environmental goals but also contribute to cost savings and regulatory compliance.

If you would like to learn more, check out our partner Elektron, which is at the forefront of this transformation, offering high-quality metal solutions tailored to meet the dynamic needs of modern industries.

3. Advanced Materials and Alloys

With the increasing demand for lightweight and high-strength materials, the industry is investing in advanced alloys and composites. These materials offer improved durability, corrosion resistance, and performance, making them ideal for applications in:

- Aerospace and automotive industries

- Construction and infrastructure projects

- Renewable energy systems

By leveraging innovative materials, manufacturers can develop products that meet stringent industry standards while reducing overall weight and material usage.

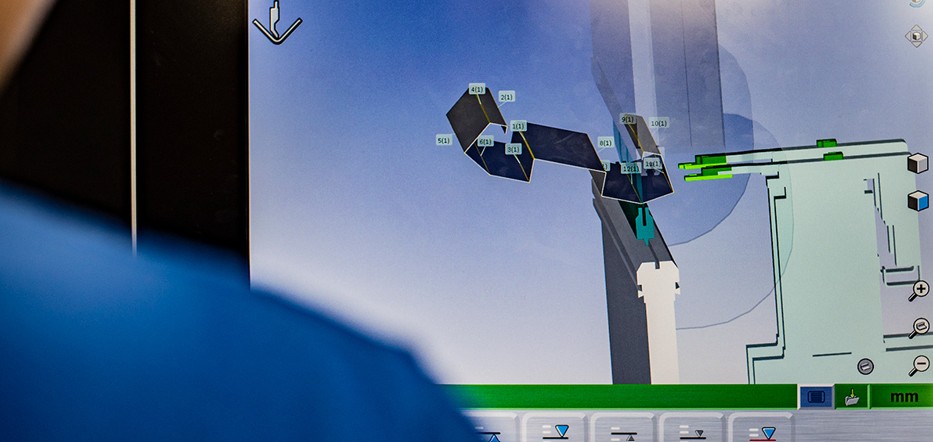

The Role of Digitalisation in Metal Fabrication

Digital technologies are transforming the way metal fabrication companies operate. From digital twins to cloud-based data analytics, manufacturers are embracing new tools to optimise production processes, enhance quality control, and improve supply chain efficiency. Some key benefits of digitalisation include:

- Real-time monitoring of production lines

- Predictive maintenance to minimise downtime

- Enhanced collaboration across global supply chains

Metal Fabrication in Various Industries

Metal fabrication plays a crucial role across multiple industries, each with unique requirements and challenges. Some of the key sectors benefiting from advanced metal fabrication include:

- Construction: Structural components, roofing systems, and architectural elements.

- Automotive: Precision parts for engines, exhaust systems, and chassis.

- Healthcare: Custom medical devices and equipment with stringent quality standards.

- Renewable Energy: Components for wind turbines, solar panels, and hydroelectric systems.

Looking Ahead

As the metal fabrication industry continues to evolve, manufacturers must stay informed about emerging trends and invest in cutting-edge technologies to remain competitive. The integration of automation, sustainability initiatives, and digitalisation will drive future growth and innovation in the sector.

For more information on advanced metal fabrication solutions, visit webelektron.com.